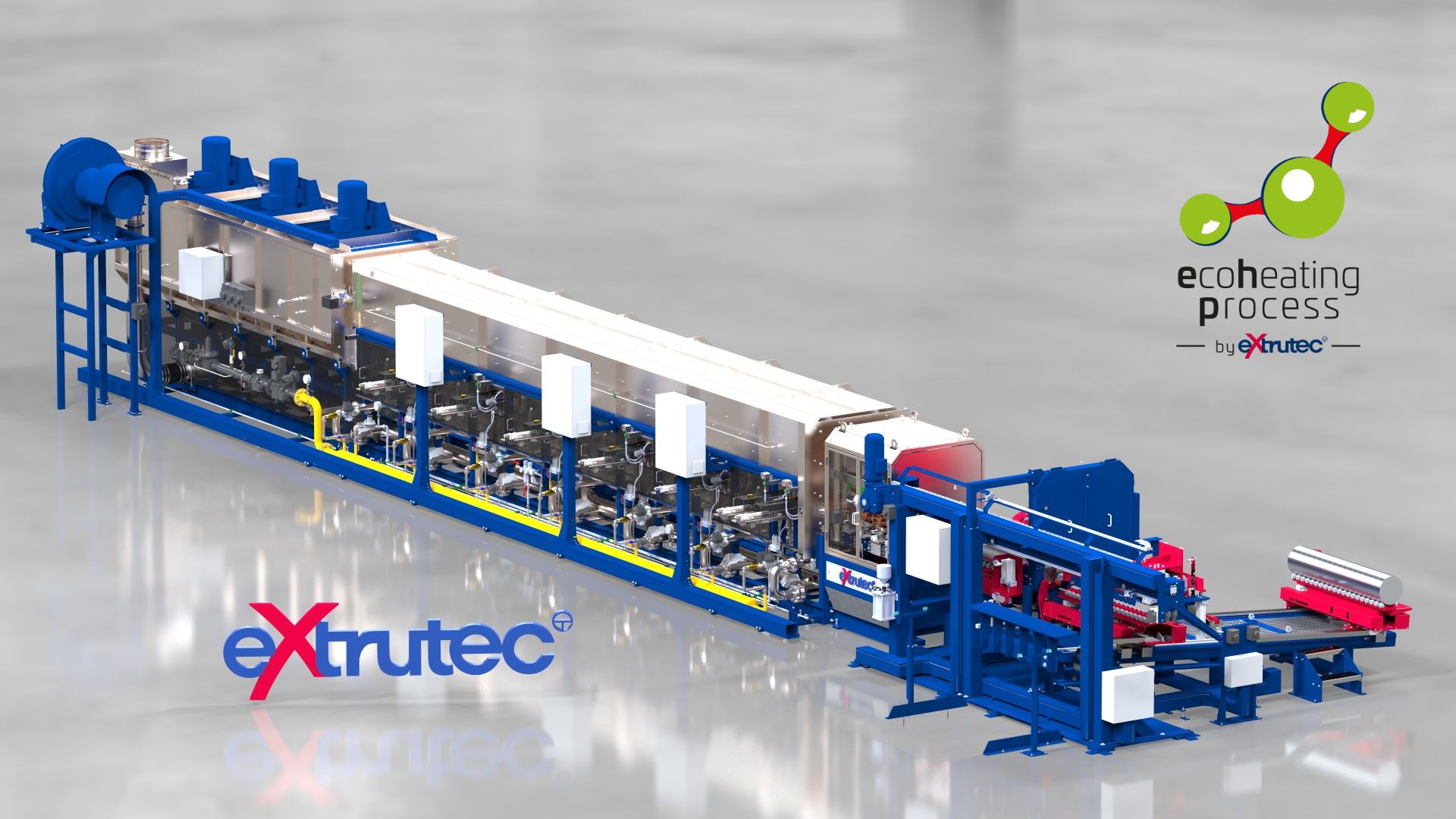

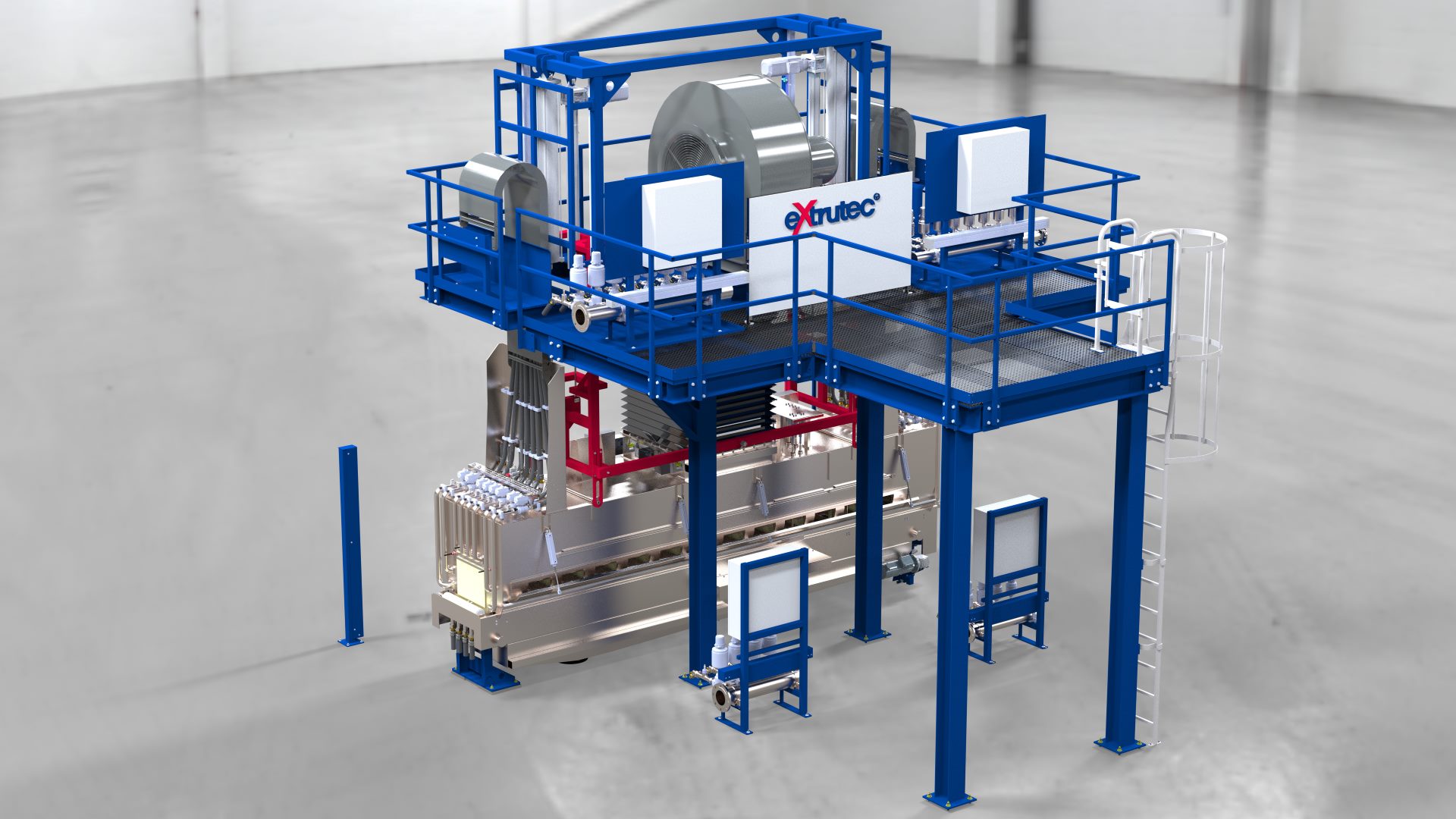

The Turkish group Kalibre Aluminyum has chosen extrutec's Eco Heating Process (EHPTM) and one of the most advanced profile cooling systems with patented Alpha Flex Technology. The system configuration, consisting of the Eco Shower Unit (ESU) exclusive to extrutec, and a gas/induction furnace with hot log saw, is characterized by the highest possible efficiency for gas-based heating systems. The Eco Shower Unit alone provides an 18% reduction in gas consumption. Downstream of the press, extrutec supplies a state-of-the-art profile cooling system with Alpha Flex TechnologyTM.

The total order consists of two identical 10 inch system configurations for the main factory in Turkey and for a new production plant in Mexico.