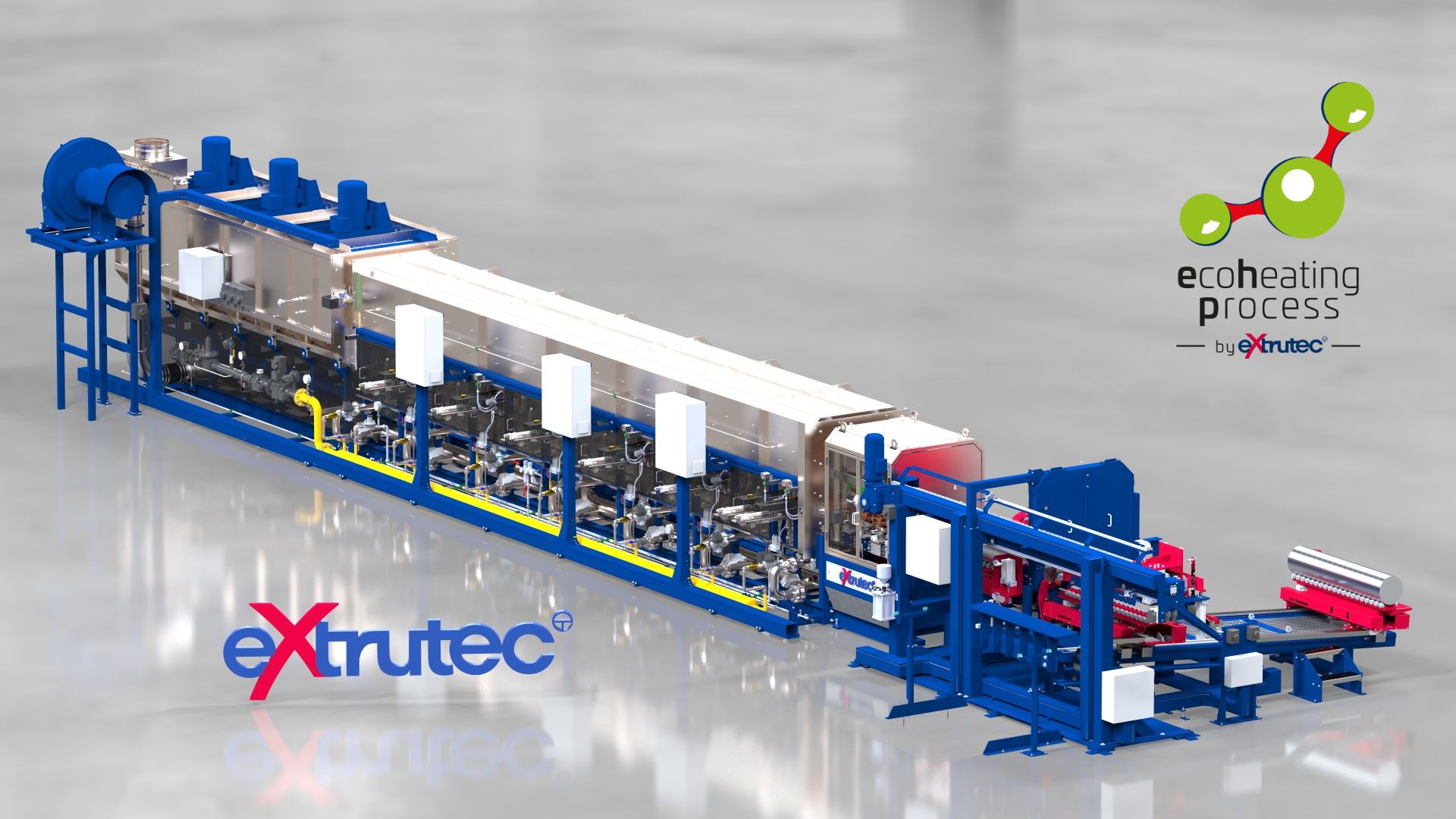

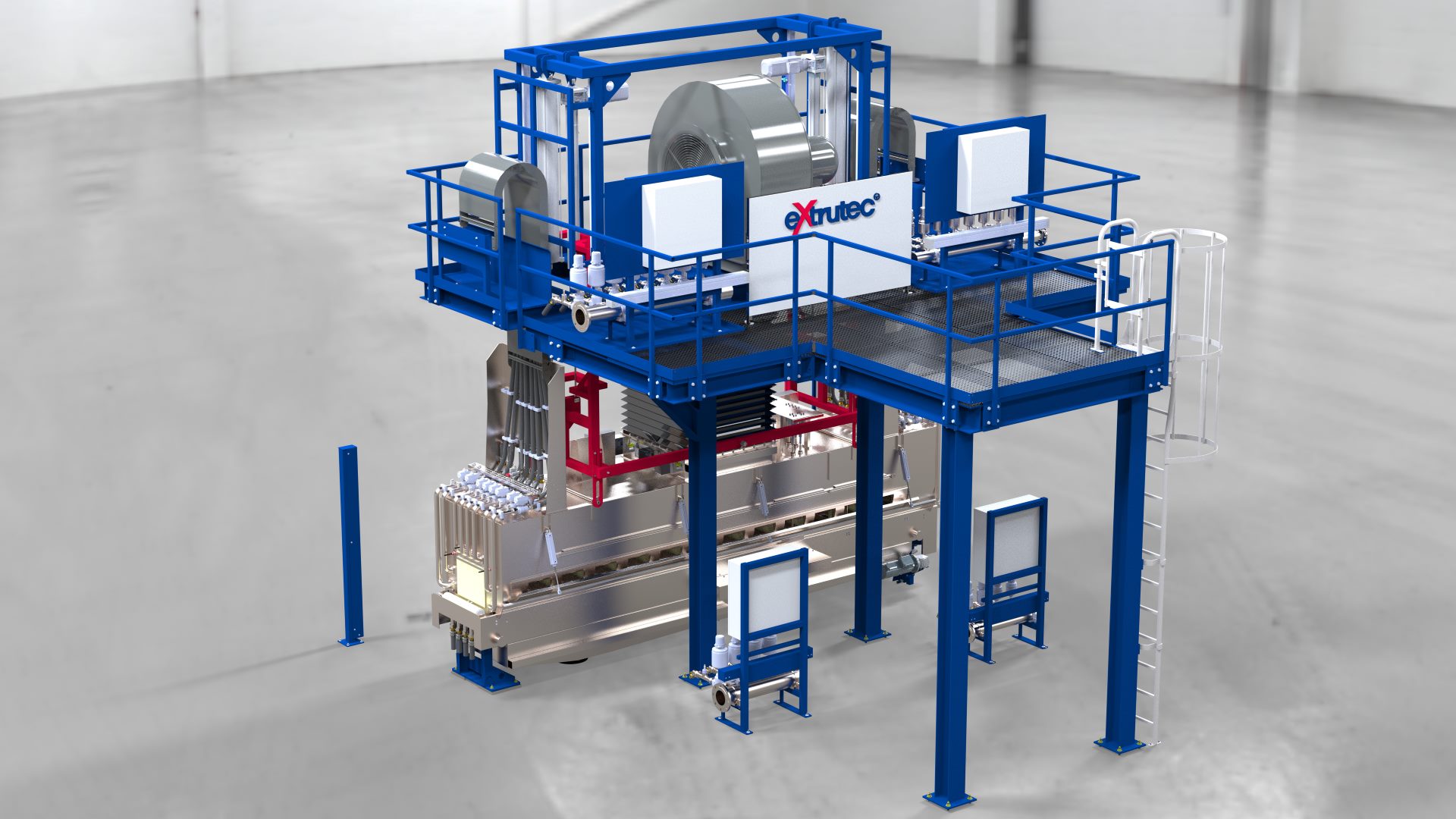

The project completion of the heating line replaced by extrutec on the P12 at Hydro's Offenburg site marks the beginning of a new era of efficient billet heating. For the project, a new Inline billet heating line (gas and induction) with hot log saw as well as a new vertical log storage system had to be accommodated in an enormously limited space. Thanks to creative solutions, extrutec's patented Eco Shower Unit (ESU) could also be installed. The ESU uses combustion gases downstream of the gas furnace preheating zone to heat water via a heat exchanger and apply it to the aluminum bars for time-optimized preheating. Hydro Offenburg made a conscious decision in favor of extrutec and this worldwide unique equipment configuration due to the long business relationship with the Hydro Group. This equipment configuration is marketed by extrutec under the brand name Eco Heating Process (EHPTM). Compared to the replaced eheating system, 36% gas can be saved while production is increased. Thanks to the new hot saw, the extrusion line can also be operated completely without billet scrap.

Due to the high resource savings, this investment in the extrutec Eco Heating Process is additionally subsidized by the government with a six-digit sum. Subsidy programs are offered in many countries and have been approved for all extrutec projects related to the EHPTM so far. More detailed information can be found on our website at: Eco Heating Process – extrutec GmbH (extrutec-gmbh.de)