PRODUCT:

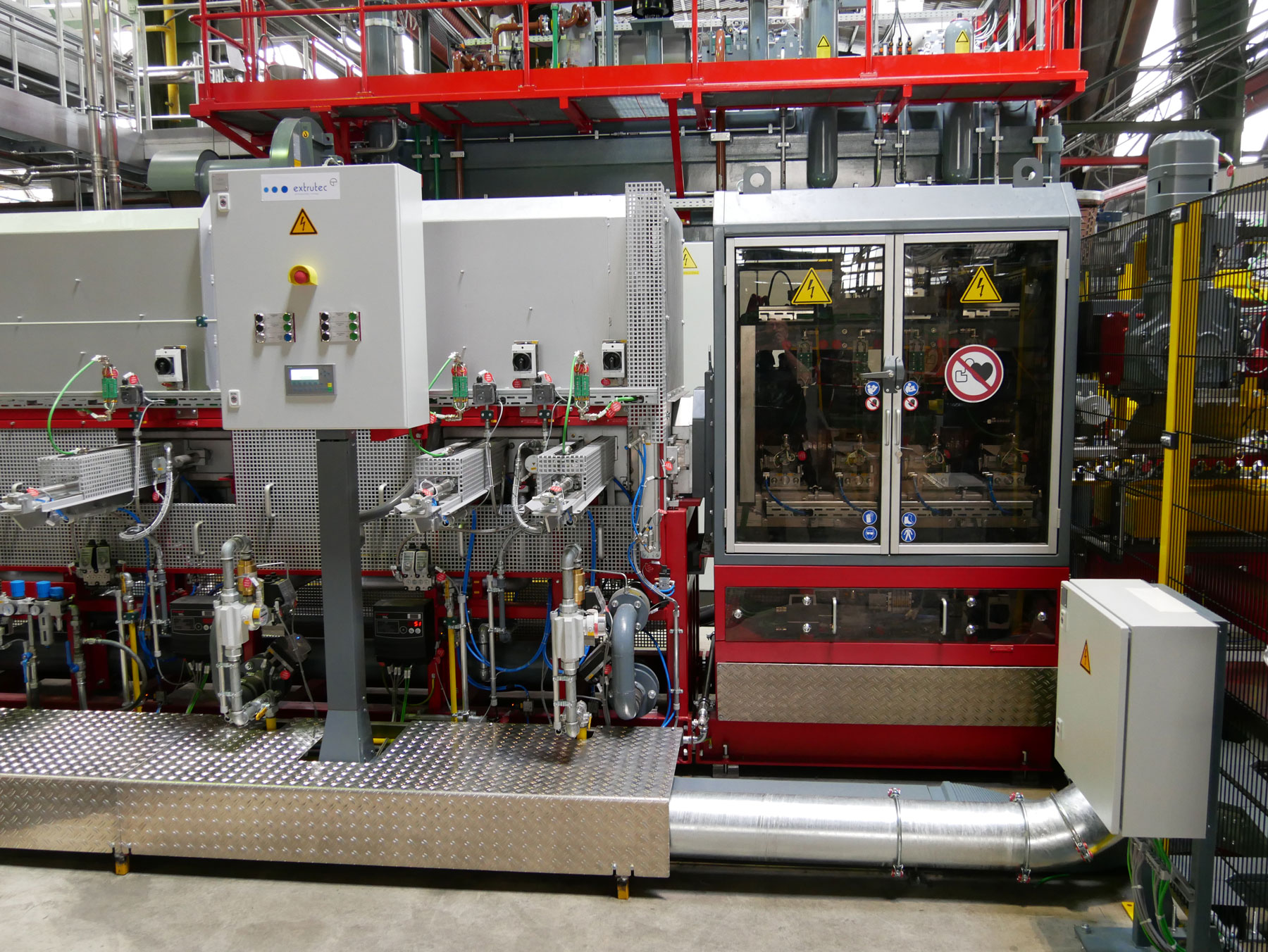

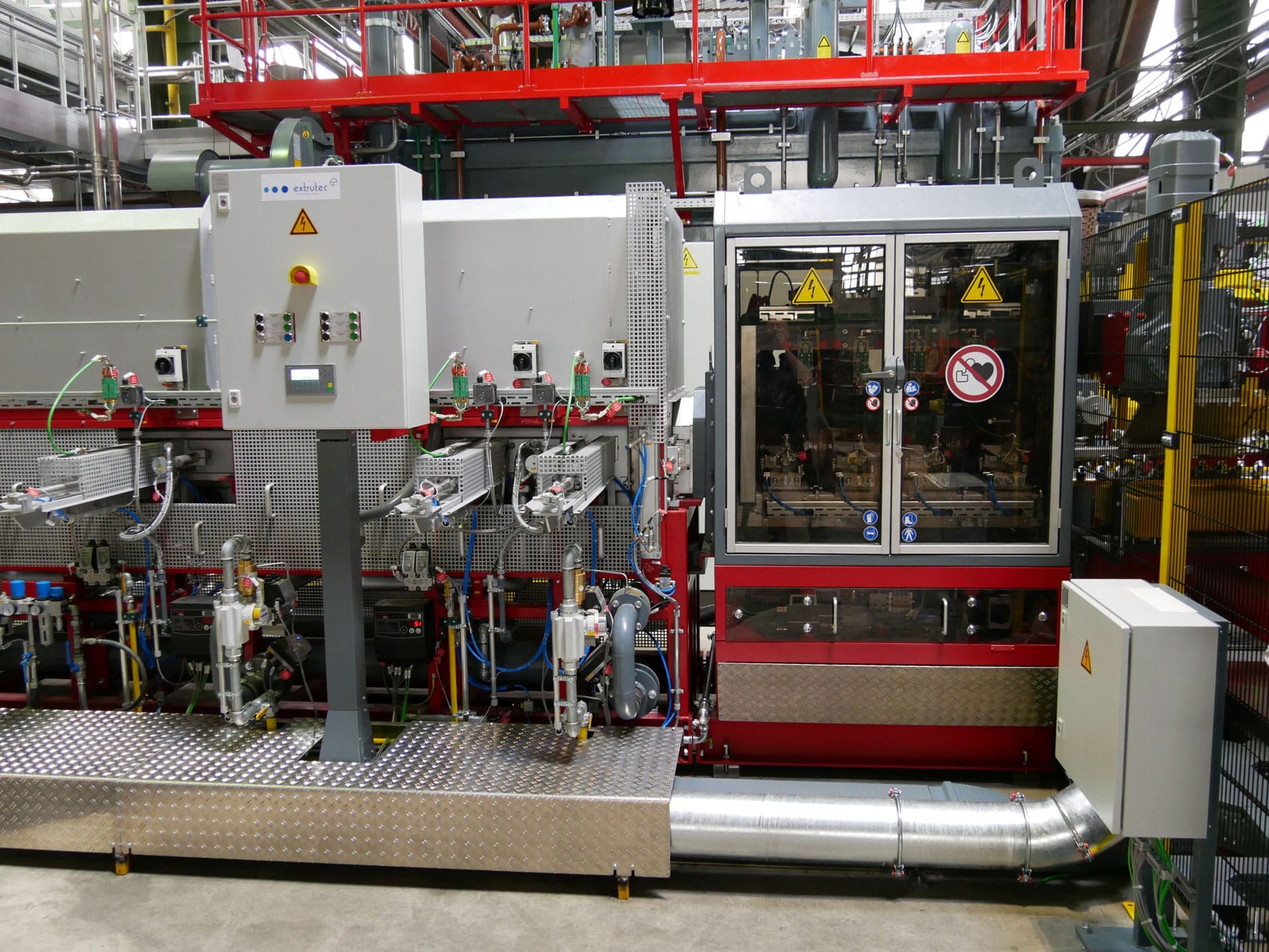

Hybrid Systems

The process-related requirements to temperature control when heating metals for forming processes have increased steadily in the last few years. An ever-increasing range of input materials and batch sizes ultimately leads to a need for considerably greater flexibility in heating concepts. The combination of gas and induction-heated heater systems performs this task with great efficiency.

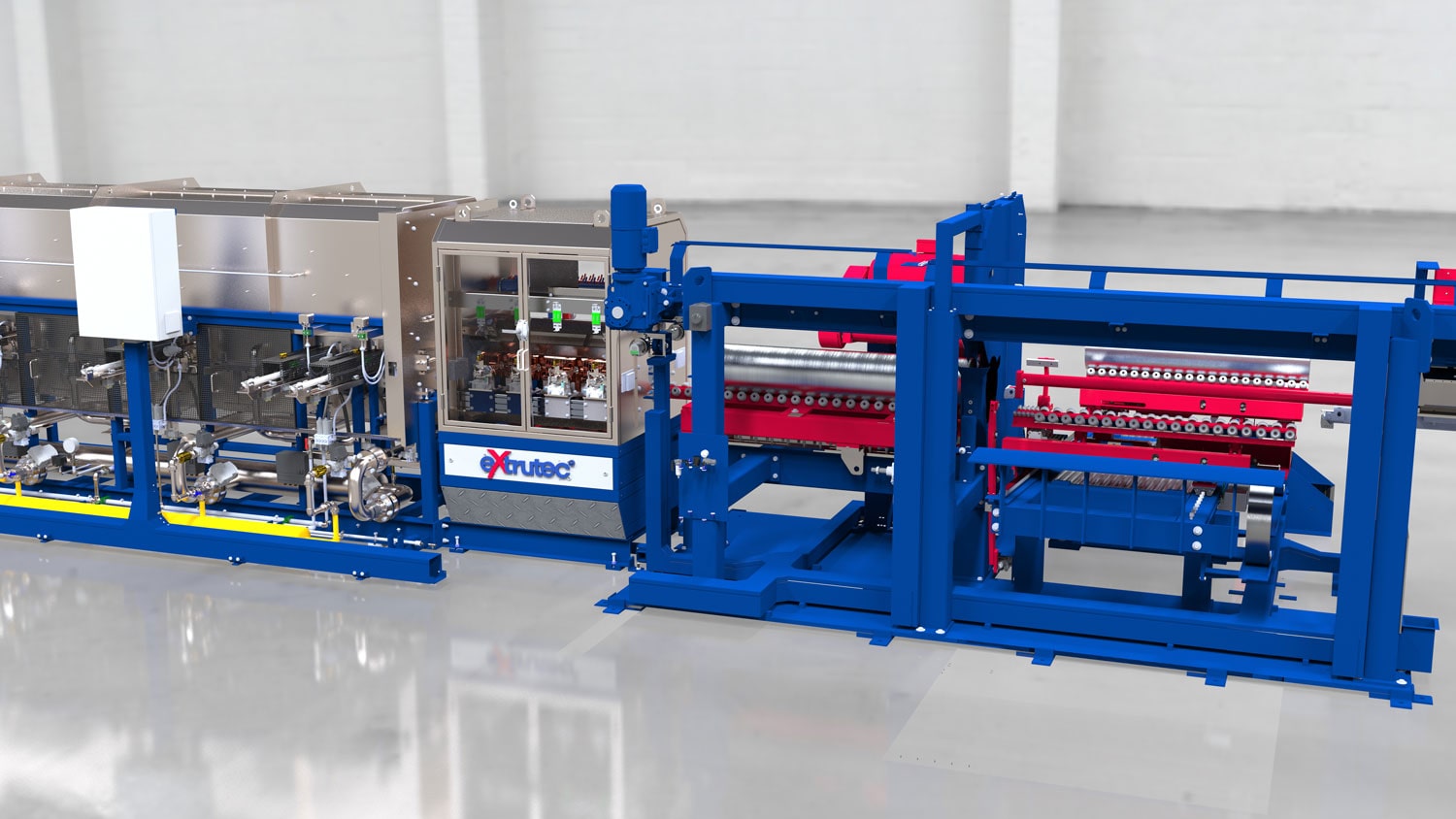

Inline Oven (worldwide patented)

extrutec has marketed the Inline furnace (In-line furnace), patented around the world, for many years. It combines a gas and induction heater arranged in line with each other. This combination has various advantages as compared to stand-alone solutions.

Special features:

- Significantly higher efficiency due to omission of the field extender

- Lower space requirement due to installation of the gas and induction modules in series instead of side by side as in the classic arrangement

- Significantly better efficiency due to the elimination of the field extender of the inuction oven (induction billet heater)

- Additional savings due to the elimination of one coilsegment and the associated reduced converter and recooling power as well as the elimination of an additional loading unit for the induction furnaceGeringer Platzbedarf

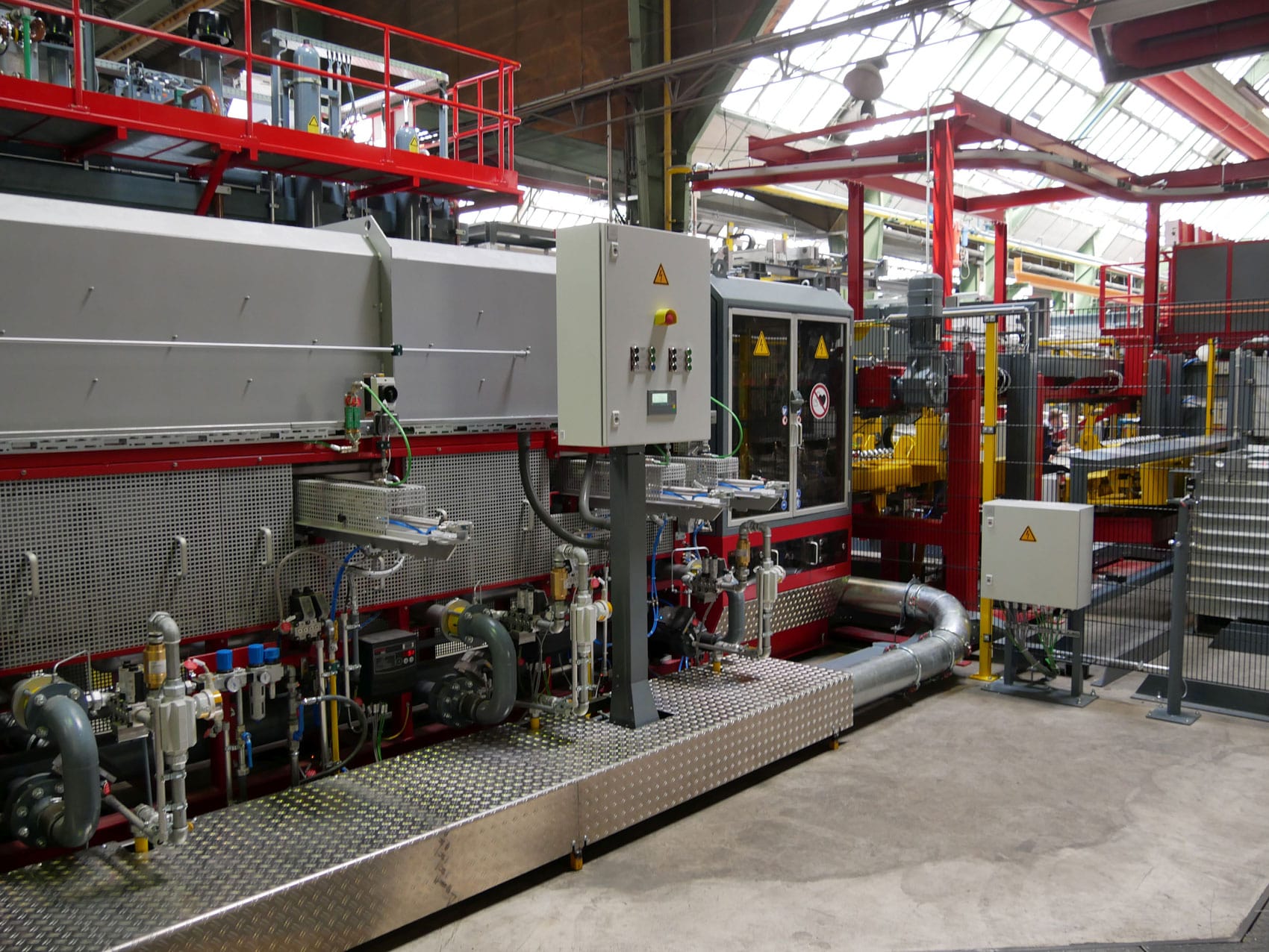

Gas Oven with Standalone Indoction Heater

Special features:

- Entirely self-sufficient heater concepts

- Redundancy

- Rapid alloy changes

- Heating of special alloys exclusively in the induction heater

- Reliable process control in required metallurgical processes, e.g. when the heating temperature is very close to the liquidus point

Both concepts have features that have been essential in the purchasing decisions of many of our premium customers in the last few years. Cost-effective basic heating with of gas and subsequent application of a precise taper or exact temperature adjustment by induction is the best heating concept currently available for most applications. These properties in the heating concept are particularly important in areas such as automotive engineering, where demands on the end product are high. This hybrid heating concept is established as the technological standard in the aluminium industry.