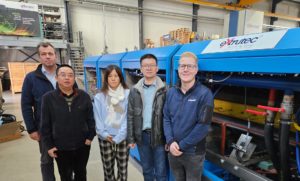

extrutec is pleased to announce the successful completion of a furnace replacement project at General Extrusions International, Inc. (GEI) in Youngstown, OH. In August 2024, extrutec was awarded the contract to replace the existing 7" induction furnace on the 1675 ton press line. The main objectives for the furnace replacement were

- Improved process reliability

- Accurate temperature uniformity

- High efficiency

To achieve these objectives, the new furnace is equipped with 5 individual heating zones for precise billet taper. The power to the multilayer coils is controlled by the latest IGBT converter technology with 5 individual outputs. The IGBT converter is equipped with an unregulated diode rectifier to achieve a constant power factor of 0.95 or better, without capacitors or filter reactors. The IGBT converter allows continuous adjustment of the power density in the coils, which in combination with the thermocouples in each coil section, provides high temperature accuracy.

Despite the challenging short timeframe, extrutec was able to deliver the equipment as promised for an installation during the Christmas shutdown. We'd like to thank the whole team at GEI for their excellent cooperation.