Further orders for profile cooling units were placed by the HAI group (main plant in Ranshofen in Austria). Continuous further development of this product group has given extrutec a special position in the market.

Category: Milestones

2011

Posted on | by WAS

The company's internationalization continues in the business year of 2011 (Incoming orders from three continents outside of Europe).

Incoming orders total in excess of almost EUR 9 million for the first time in the company’s history in 2017. the number of employees increased in this business year as well.

Incoming orders during the full year will reach a record level of almost EUR 9 million and the number of employees also increased in this business year. For the first time, sales exceeded the 5 million mark in 2011.

Orders from China, Australia and the Netherlands

- First order from China is placed by Bejing Erbslöh China (Joint Venture with existing customer Erbslöh Aluminium from Velbert)

- Capral (largest and most important manufacturers of AL extrusion profiles in Australia) orders a gas heater system with hot shear from extrutec

- A order for gas heater system with triple gas taper, hot shears and vertical magazine for rods was placed from South America (Hydro Aluminium Acro near Sao Paulo, Brasilia)

- Nedal Aluminium from the Netherlands placed an order for another in-line heater with hot saw. With a rod and log diameter of 14" (357 mm), this is the largest active in-line heater system to date.

2010

Posted on | by WAS

The year of 2010 set the tracks for extrutec and its market position. Continuous new and further development of plants, as well as permanent dialogue with customers, led to the development of highly successful products, within in turn significantly generates orders. In this context, the number of employees almost doubled during this period.

Further Orders

Early in the year, Kety group from Poland placed their first order for an Al hot saw combined with an extrutec gas heater. The saw is equipped with horizontal stroke. All hot and cold log saws in the years to come will subsequently be designed as swivel versions, which offer considerable space advantages.

During the year:

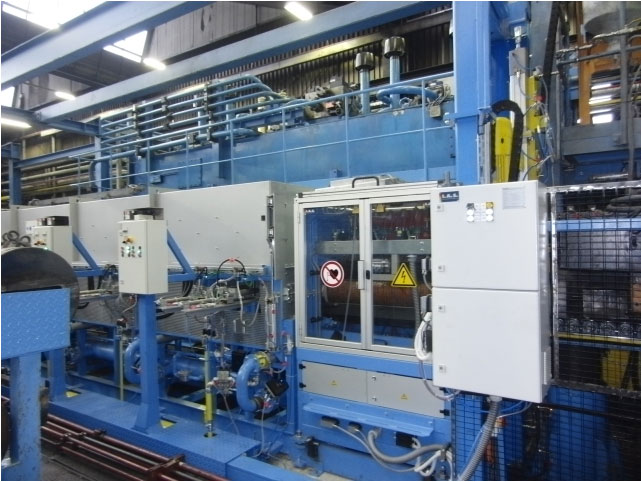

- Alcan (now Constellium) from Crailsheim orders the first In-line heater

- Thöni from Telfs, Austria, orders a total of 5 gas-fuelled ageing ovens

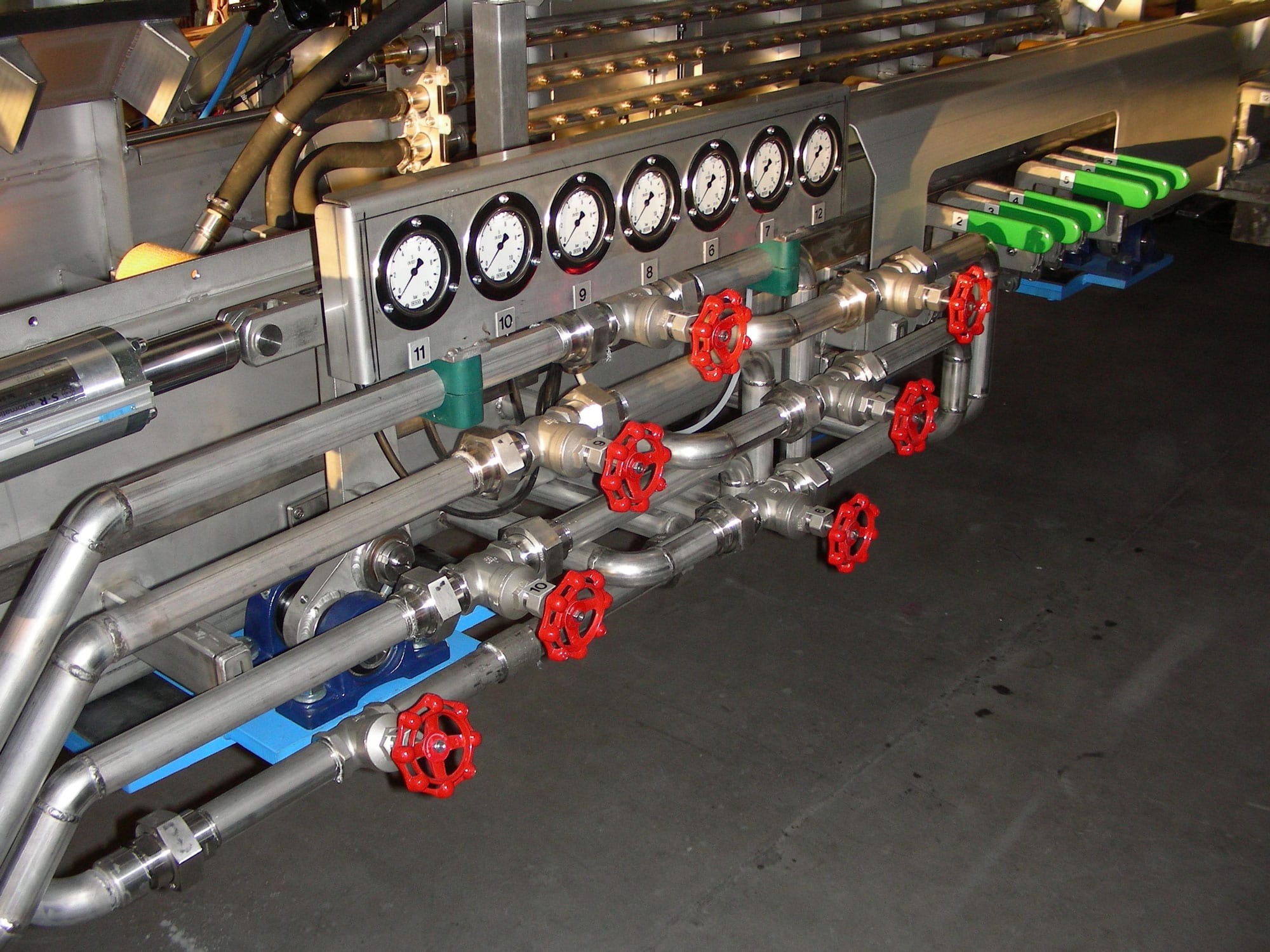

- Erbslöh Aluminium from Velbert orders the first high-pressure cleaning systems for rods and logs

- apt Hiller (now apt Extrusions GmbH & Co. KG) orders the first die heater from extrutec

2009

Posted on | by WAS

The first order for a log heating system was placed by a customer outside of Europe (Alupco from Saudi Arabia for its Jeddah plant).

2008

Posted on | by WAS

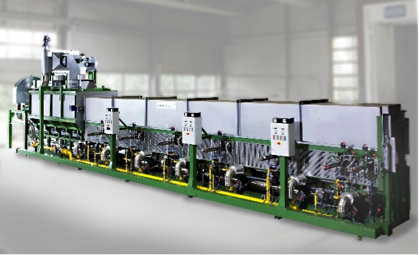

The first order for a profile cooling system for the production of crash-capable Al-profiles was placed by FW Brökelmann from Germany. Further orders for gas-fuelled log heating systems were received from Hydro Aluminum Chrzanow in Poland and Erbslöh Aluminium in Velbert, Germany.

The début of a world novelty

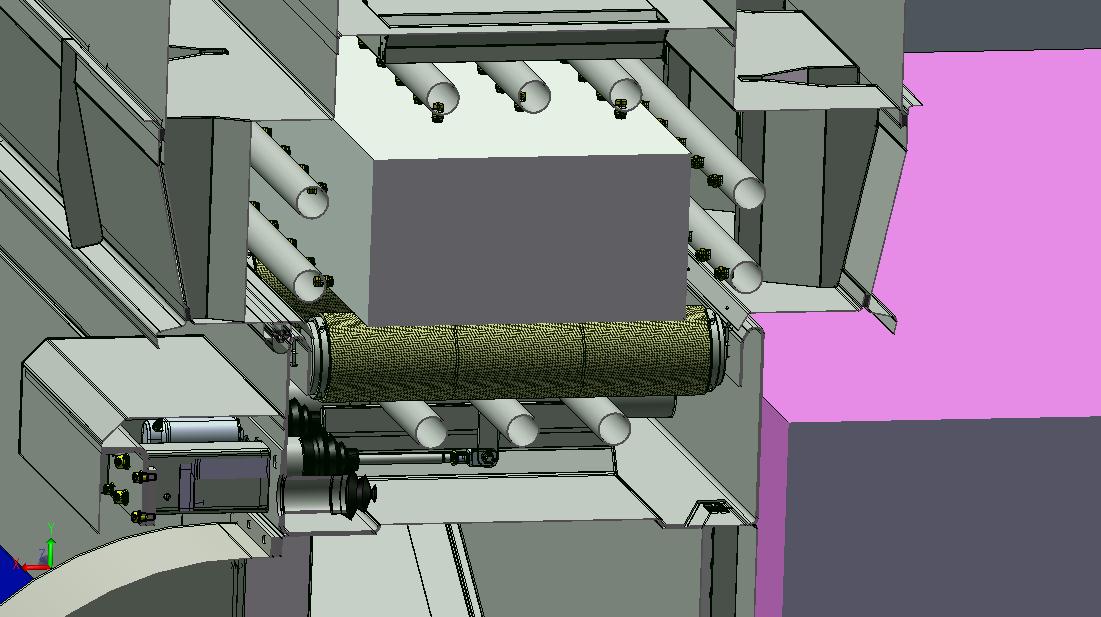

Presentation of a world première at the aluminium trade fair in Essen. Together with IAS from Iserlohn, we developed a combination of a gas and induction heater arranged “in line” was developed and presented it to the experts.

In 2008 sales have doubled.

2007

Posted on | by WAS

The first two orders for the newly developed gas-fuelled heater facilities with hot shears were placed by Aluminium Menziken from Switzerland.

Further facilities and newly designed water quench system

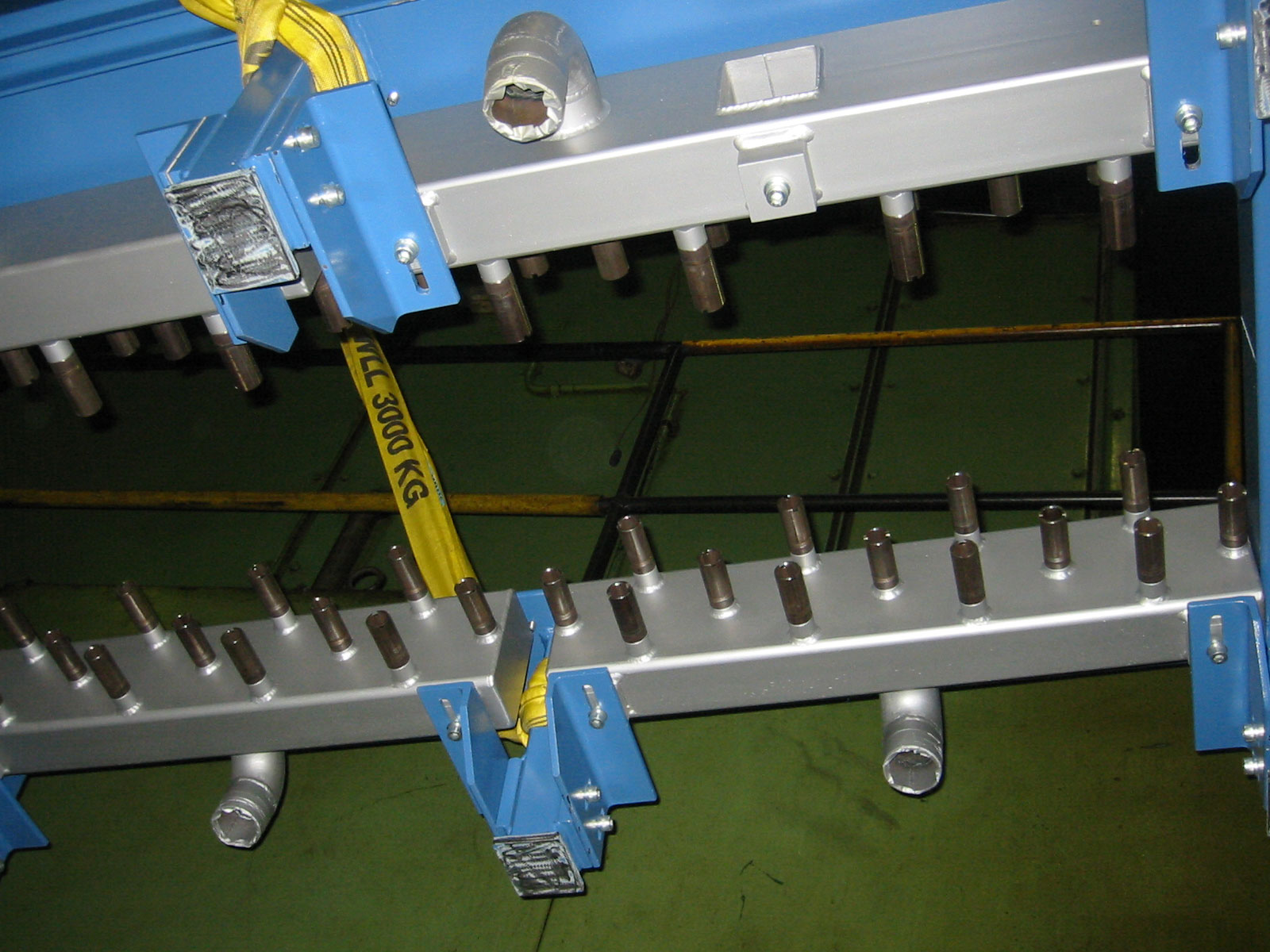

A total of 8 orders for new gas-fuelled heaters were placed in the course of the year (2 x Aluminium Menziken, Thöni from Austria, 2 x ASAS from Turkey, Purso and Nordic Aluminium from Finland, and FW Brökelmann from Germany). We also received our first order for a newly designed water quench system for intensive and extremely flexible cooling of AL extrusion profiles by Honsel (now Hammerer Industries Germany) in Soest.

Sales for 2007 are already more than twice as much as in the previous year.

2005 / 2006

Posted on | by WAS

Development of a gas-fuelled log heating system for aluminium alloys with a new type of transport system, gas burners, and their optimised arrangement in the heater area and its introduction on the market. In addition, extensive activities in the area of spare parts and services as well as optimisation of various existing heater brands.

September 2006

Joachim Sokoll enters the company as technical manager (after working as head of design at Elhaus Industrieanlagen GmbH for more than a decade before). The sales volume exceeded the one million for the first time in 2006. Further personnel were recruited as well, in particular new colleagues with comprehensive industry knowledge.