PRODUCT:

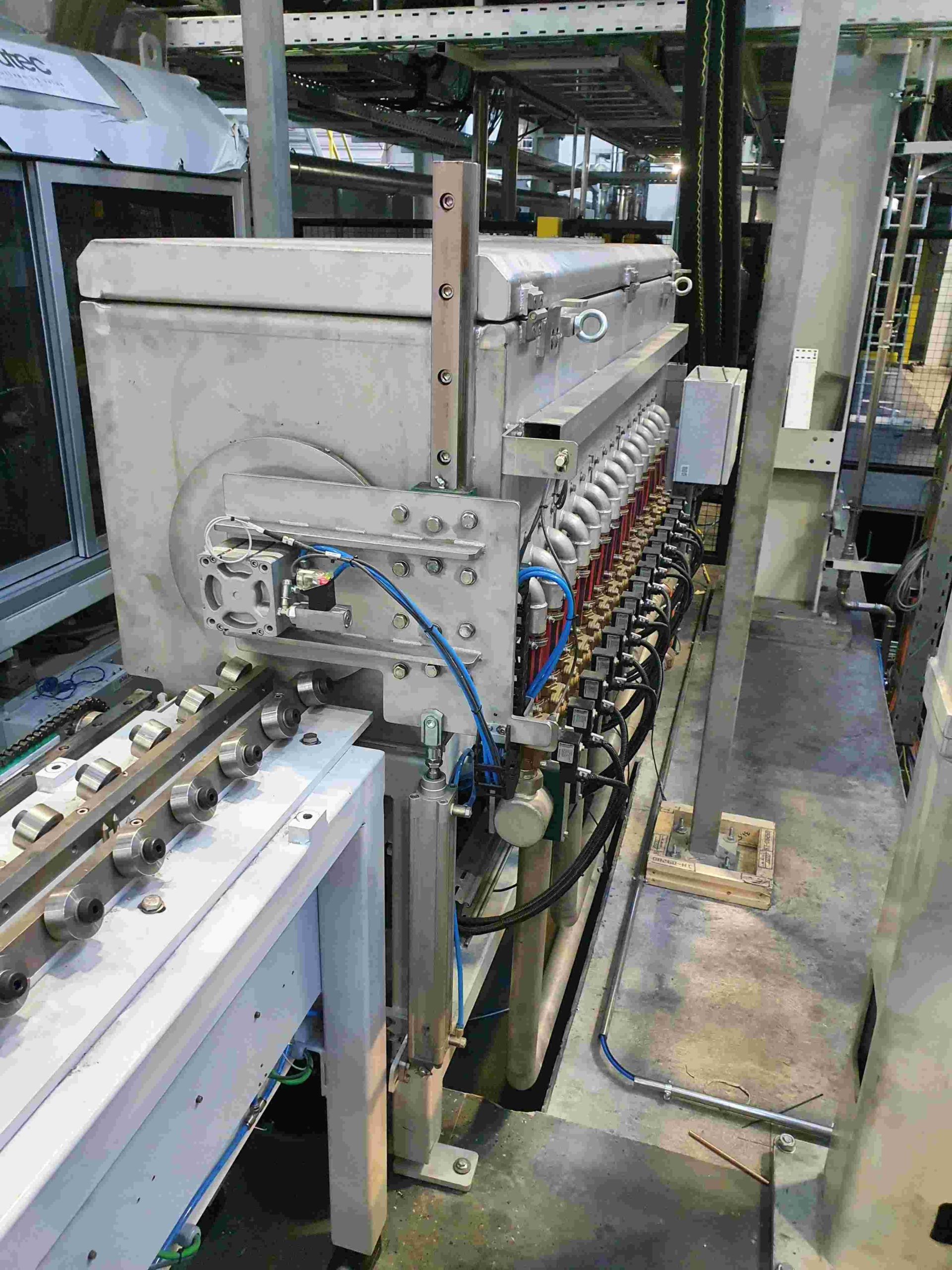

Taper Quench

The extrutec taper quench will give sophisticated extrusion plants two key benefits. Using a billet with a temperature taper will allow for an isothermal extrusion process. At the same time, creating the temperature taper by quenching the billet, creates a unique microstructure.

extrutec Taper Quench

Special Features:

- the billet to be tapered is heated to the required temperature by the gas- /induction furnace

- an integrated temperature measuring device measures the actual billet temperature

- the quench consists of a stainless-steel housing with 5 quench zones

- each zone consists of 3 ring-segments, equipped with nozzles providing a full cone spray pattern

- each zone is supplied with water via an individual proportional valve and is equipped with a flow meter and temperature probe

- a fan feeds the water vapor to a condenser and the Condensate is fed back into the tank

- once the desired temperature gradient is achieved, the billet is transferred to the press