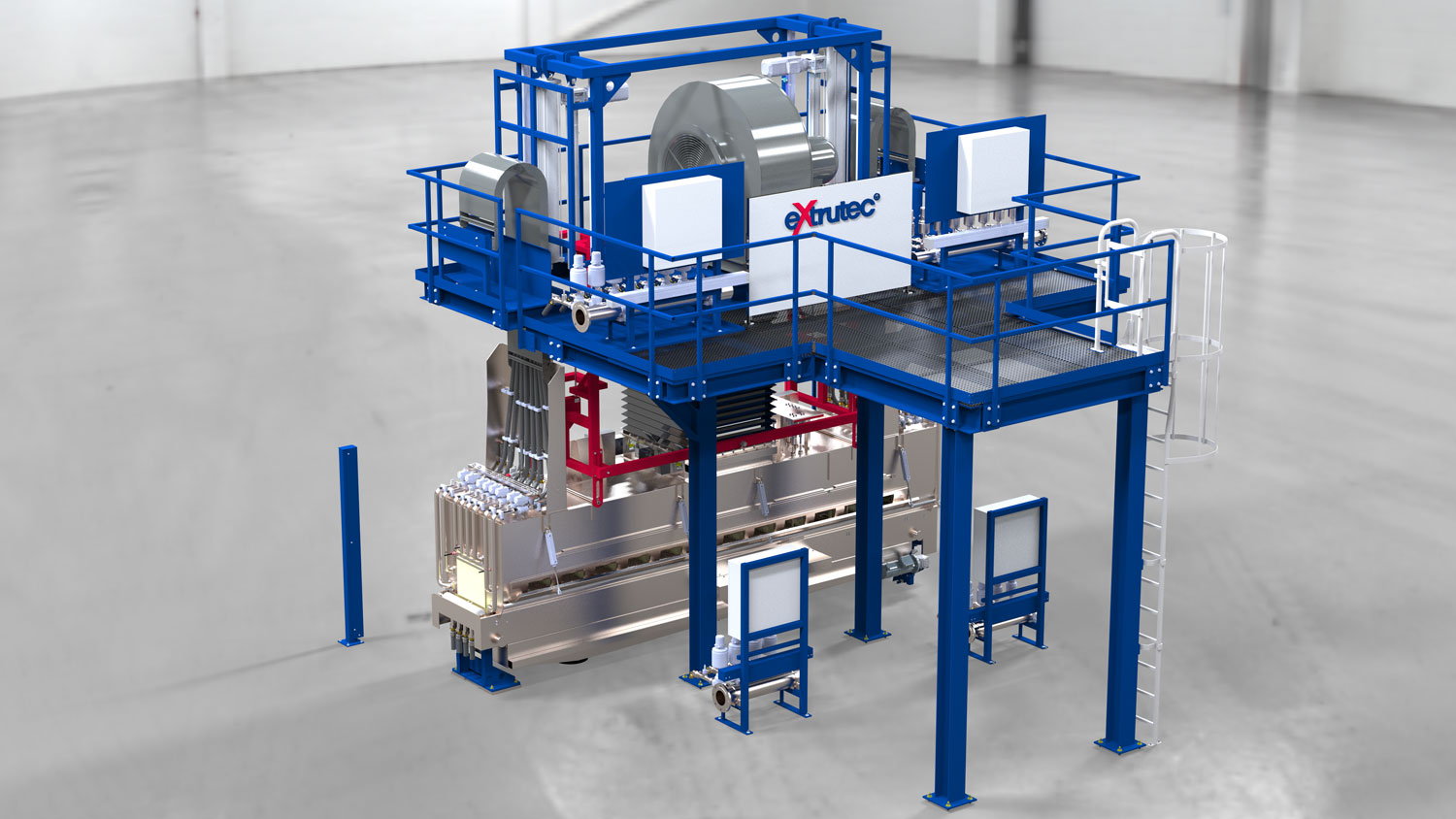

PRODUCT:

Profile Cooling

„Worlds most advanced profile cooling“

We are well familiar with material strength, ductility, and dimensional stability. Our sophisticated profile cooling systems provide the right answers.

Profile Cooling

Special features:

- In parallel to the profile course, water quench nozzle holders arranged on all sides and swivelled by motor

- Multi-zone division with proportional pressure control

- Optional visualisation of the profile geometry (real data)

- Use of “inoculated” air with high impact velocity

Constant material optimisation of profiles leads to ever higher demands on plant technology, in particular concerning the flexibility of cooling. This is a challenge that we rise to every day.

NEW TECHNOLOGY:

Alpha Flex Technology

The Alpha Flex Technology is a technical extension of the existing profile cooling system from extrutec. In the future, the axially rotatable nozzle will consist of a two-chamber AL extruded profile.

In the large chamber 1, solid jet nozzles are still used, with which a very high α-value of at least 7,000 W/m2K is achieved for the most intensive water cooling (typical nozzle size V=6/l/min at 7 bar).

In the future, extrutec will close the previously very large "α-gap" between air and water cooling with soft cooling using the patented Alpha Flex Technology with α-values of 500 W/m2K to 1,000 W/m2K (typical nozzle size V=1.3/l/min at 7 bar). Here, water nozzles with very low flow rates are used in the small chamber of the double profile to produce a fine spray cone. These are brought into position by simply rotating the 2-chamber profile axially by 180°, and can of course also be swiveled (+/- 20°) to adapt to asymmetrical profile geometries. Depending on the application, the cooling intensity of Alpha Flex Technology can be adjusted to values less than 500 W/m2K or greater than 1,000 W/m2K by selecting a different nozzle size.

The following heat transfer coefficients are achieved for the individual variants:

- Water quench (full jet nozzles) α at least 7,000 W/m2K (39,750 BTU/h ft2 F)

- Soft cooling water mist Alpha Flex Technology (new patent) α 300 W/m2K to 1,500 W/m2K (1,700 and 8,500 BTU/h ft2 F), depending on nozzle size

- Intensive air cooling (at vair = 50 m/s) α up to 200 W/m2K (1,140 BTU/h ft2 F)