PRODUCT:

Log Cleaning Systems

Extrutec high-pressure cleaning systems are used by a large number of customers. All possible impurities are removed from the logs and billets before they enter the heating furnace. Sand particles in particular are removed. An advantage that is clearly noticeable is the service life of the extrusion dies and in the quality of the profile surface.

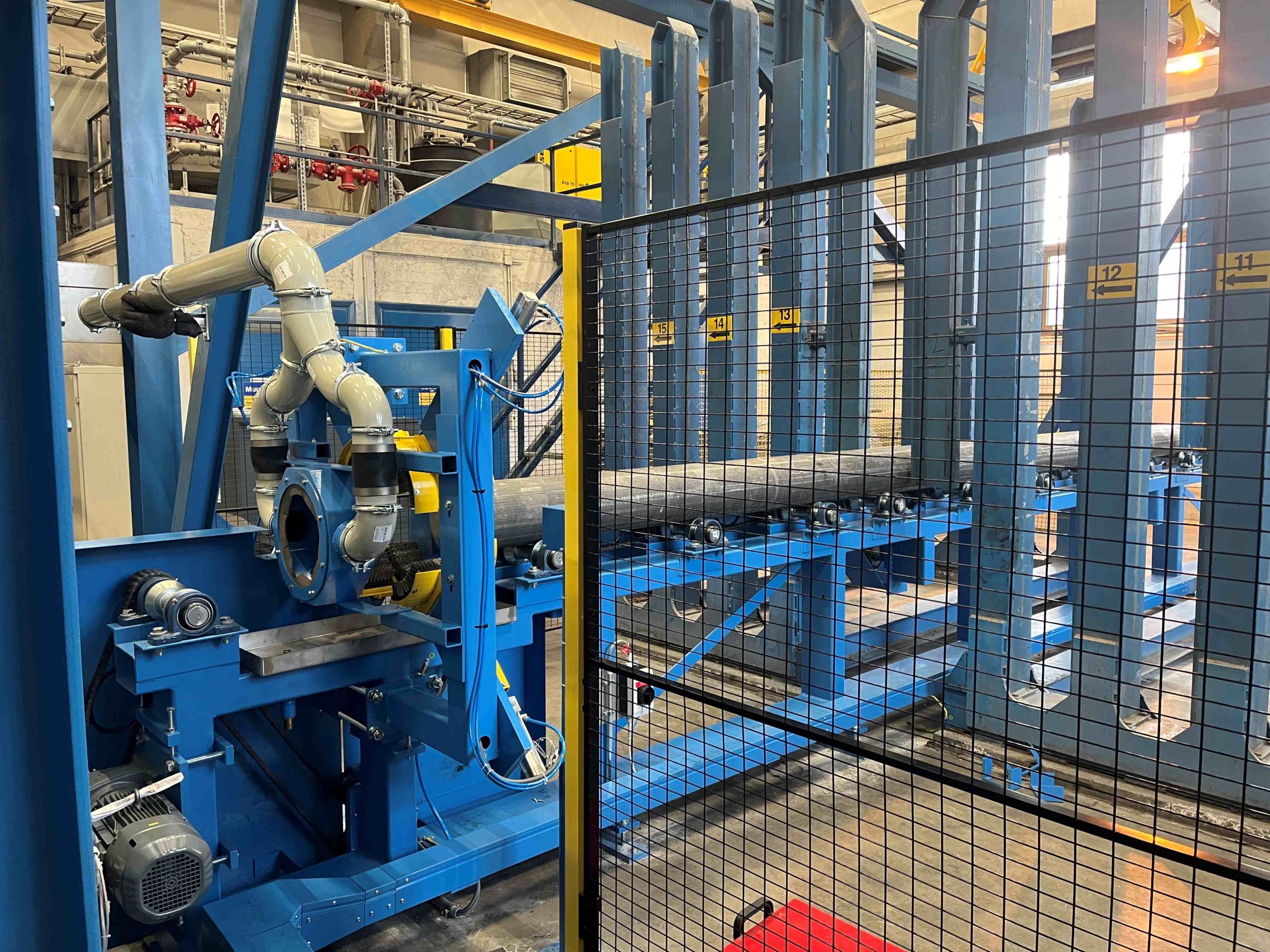

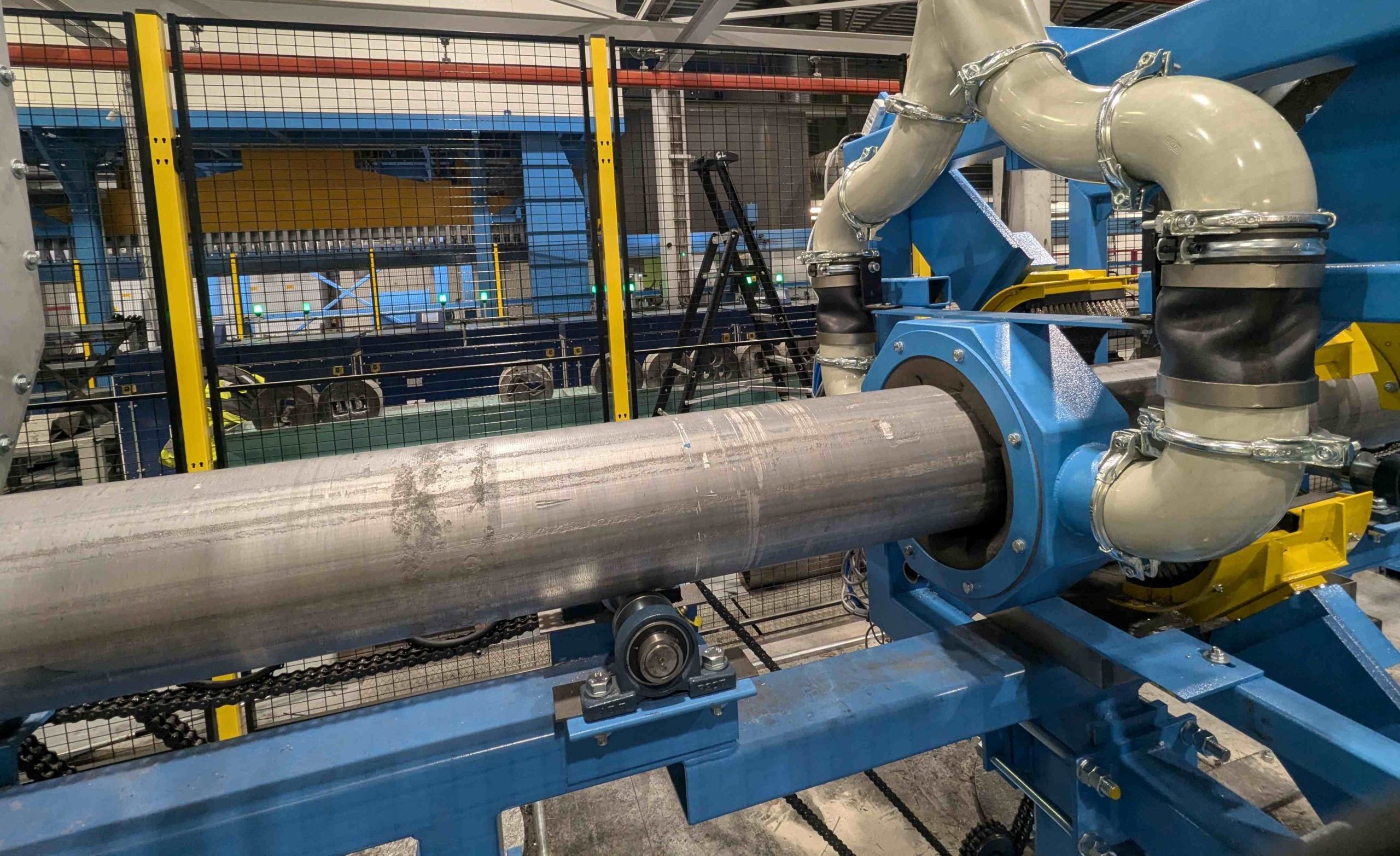

High-pressure water cleaning systems

Special features:

Extrutec high-pressure cleaning systems use hot water and a pressure of 210 bar to effectively clean the logs/billets of any contamination. High-pressure cleaning does not damage the rough cast surface, which results in a significantly higher efficiency of the gas furnace. The high-pressure cleaning system is equipped with an automatic filter integrated into the closed water circuit as standard. The systems can be integrated into an Energy Saving Unit (ESU) or used as a stand-alone variant.

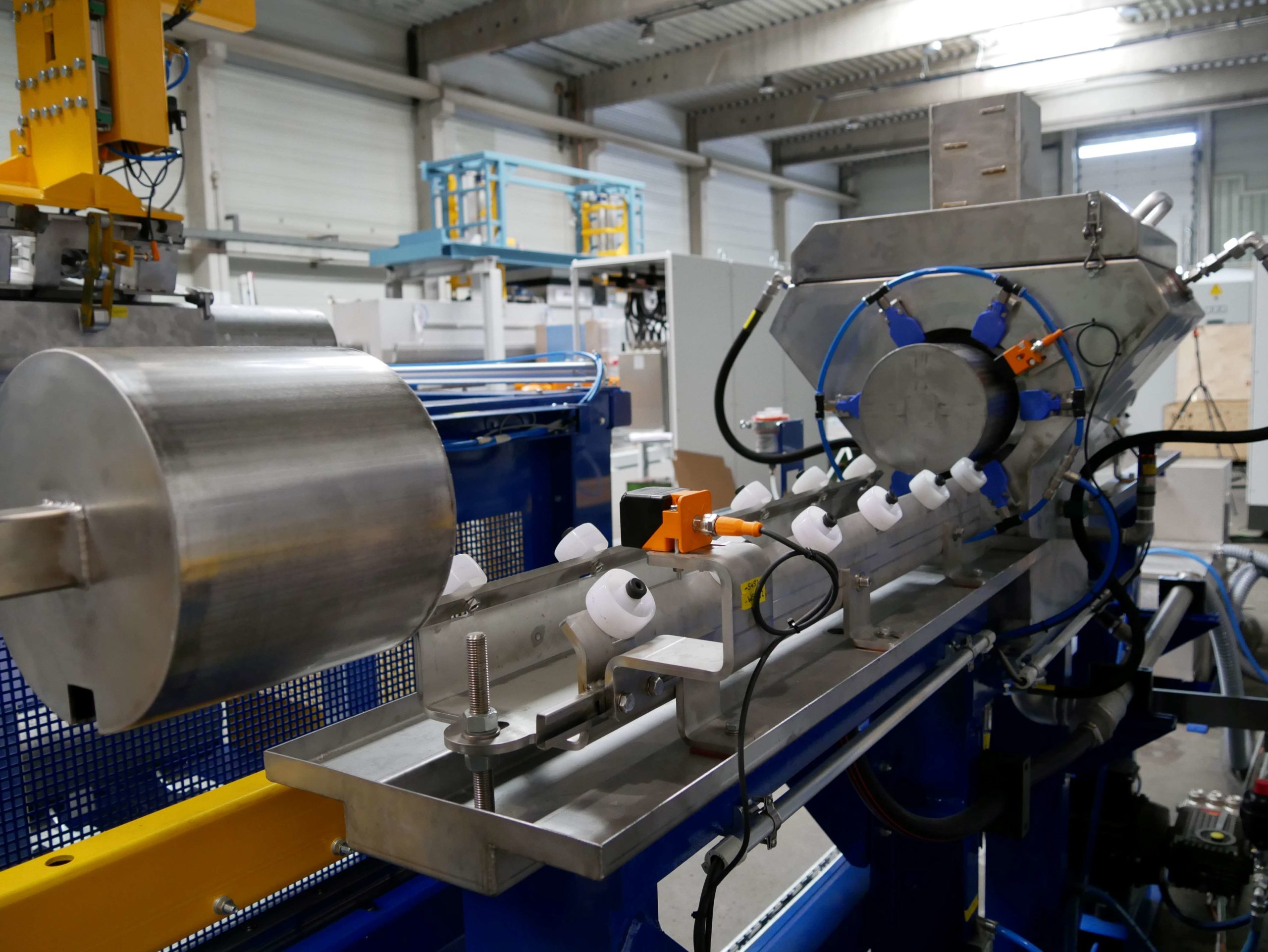

New mechanical log cleaning (no rotation):

Special features:

Special stainless steel brushes (long service life) are used, which are pressed against the bar with pneumatic cylinders. This ensures a uniform cleaning result. The supplied suction device requires a power connection of 3kW. The suction capacity is approx. 2000 m3/h. In contrast to high-pressure cleaning, this is a significant cost and energy saving. The surface of the logs is also not damaged.

News