PRODUCT:

Ageing Ovens

Different oven concepts are used depending on the space required and transport logistics. In addition to simple floor-mounted ovens with longitudinal transport by roller conveyors, overhead ovens loaded either by way of scissor lifts or vertically suspended hydraulic cylinders are also used. Third version available are ageing ovens with side- opening doors served by an automatic shuttle. These systems are characterized by a particularly low overall height and are thus also well suited for retrofitting in older buildings. Regardless of the transport concept, extrutec heaters are cross-ventilated by default. These ovens operate on the principle of double air flow. This means that the two rows of baskets placed next to each other are each flown through separately. In addition to the ageing ovens, our portfolio also offers annealing ovens.

extrutec Ageing Oven System in floor mounted configuration with laterally opening heater doors and shuttle system

Characteristics and functional description:

The batches to be aged are removed from the storage and are assembled manually by means of a building crane (alternatively fully automatically via a higher-level control system and automatic crane) on so-called storage benches. From there on they are then picked up by a floor-guided shuttle system and transported in front of the selected ageing oven. The shuttle positions itself in front of the selected storage station and is firmly locked there. The assembled stacks of baskets (2x4 baskets are to be aimed for) are then picked up and positioned on the shuttle carriage by means of an electro-hydraulic driven lifting device that is integrated in the shuttle. The shuttle then travels with the batch parallel to the ageing oven system until it is positioned in front of the selected aging oven. From there, the basket stacks are loaded into the respective oven chamber and the ageing cycle starts after the shuttle is out of the door range and the oven door is closed The shuttle then continues to the next selected target position. After completion of the ageing cycle, unloading takes place in reverse order. The batches are again picked up fully automatically and temporarily stored on another free storage bench for cooling and ongoing transport.

extrutec Ageing Oven System in overhead configuration with hydraulically operated scissors lifting table

Characteristics and functional description:

The batches to be aged are removed from the storage and are assembled manually by means of a building crane (alternatively fully automatically via a higher-level control system and automatic crane) on so-called storage benches. From there on they are then picked up by a floor-guided shuttle system and transported in front of the selected ageing oven. One individual hydraulic scissors lifting table with fix mounted oven door on top is installed under each ageing oven chamber. Die vorbereiteten, auszulagernden Chargen werden dann (Mittels einer elektromotorisch verfahrbaren und hydraulisch Heb-/ und senkbaren Hubeinrichtung, welche in das Shuttle integriert ist) auf den abgesenkten Scherenhubtisch mit Ofenboden platziert. The prepared batches to be aged are then placed on the lowered scissors lift table by means of an electro-hydraulic lifting and transport device that is integrated in the shuttle. After the loading process is completed, the oven doors are closing automatically and the selected heat-treatment program is started. After completion of the ageing cycle, unloading takes place in reverse order. The batches are again picked up fully automatically and temporarily stored on another free storage bench for cooling.

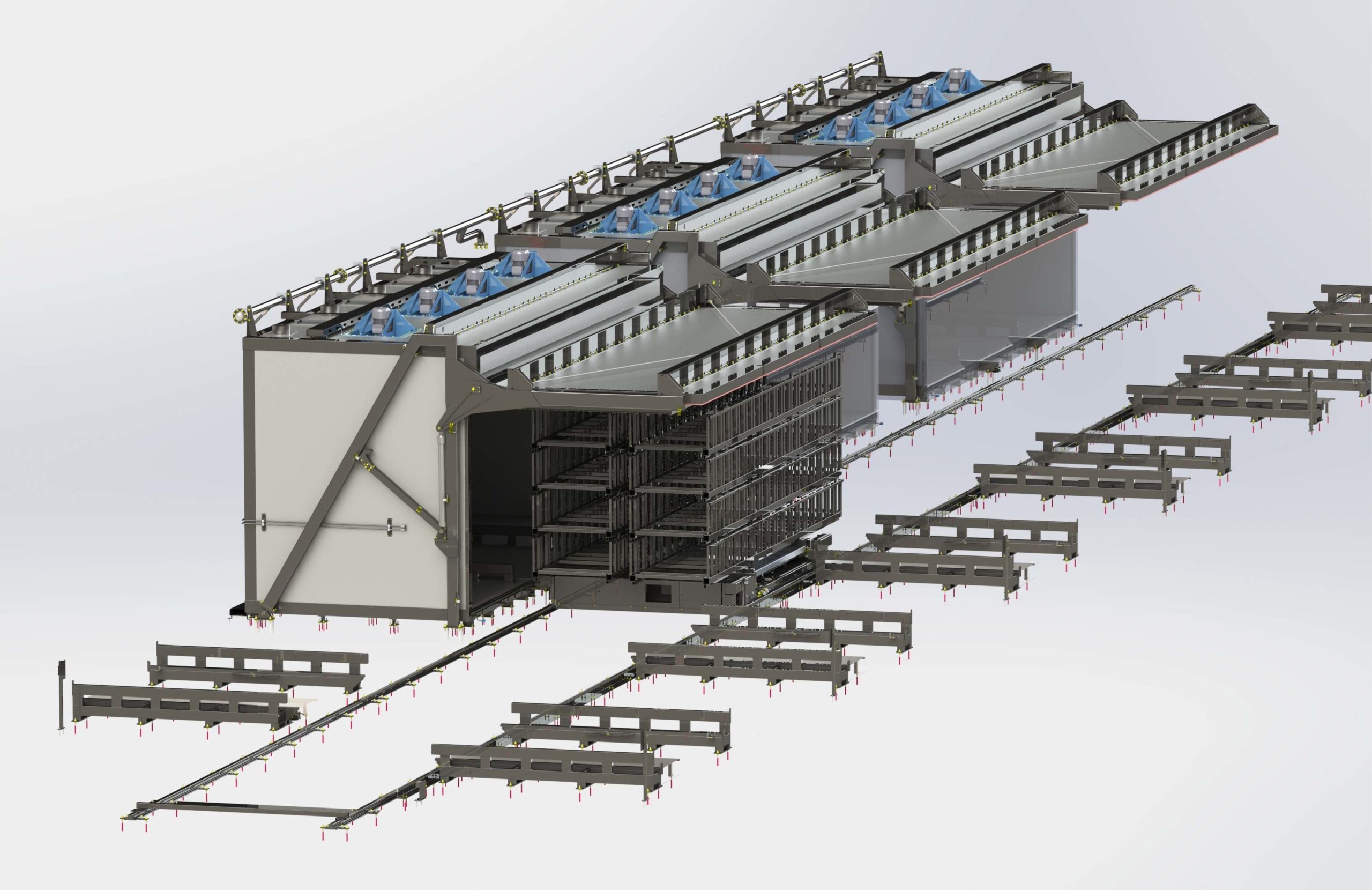

extrutec Ageing Oven System in floor mounted configuration with basket conveying systems and shuttle system

Characteristics and functional description:

The batches to be aged are removed from the storage and are assembled by the operating personnel directly on the roller tables in front of the furnace system by means of an overhead crane. The ageing process can then be started manually and runs according to a predefined routine. The assembled batches then move in automatic mode by means of floor conveyor technology (chain or roller design) into the preheated furnace chamber and the heat treatment process starts after closing the furnace door. After completion of the ageing process, the batches are moved out in reverse order onto the floor conveyors behind the ageing oven system.

News